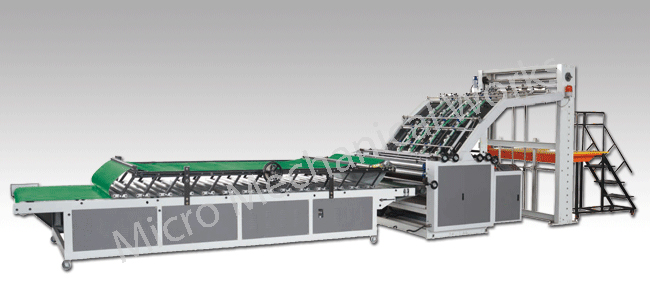

The top paper can pile up the height of 1.5m once time,it makes delivery more easier and efficient.

Using suction feeding automatic of bottom sheet,according tothe main machine operating speed,continuous automatic tracking.

Entire new concept ,front asuge registration,position high accuracy,bottom sheet never exccdes the top sheet.

Machine uses touch-screen/PLC cibtrol system,eh circuit system is stable and can automatically display the failure alarm.

The automatic replenishment system of glue can be added automatically during glue losses and recycing with glue to avoid loss of waste.

The scientic design of the metering folleer speed to ensure the glue evently on the same time,to avoid rejection of glue at high speed.

Floating removable press,to ensure that laminated paper will not be crushed and also keep ht carboard smooth and straight;unilateral adjustment by way of adjustment worm roll lamination pressure for quick .

Control of water lank cleaning cycle using an independent method ,clean,hard,rubber product.

Suitable for color top shet 175-500g and A/B/C/D/E/F corrugated paper laminating Color top sheet 175-500g and grey cardboard paper laminating.

1001 & 1002 Kanakia Atrium 2,

Next to Courtyard Marriott,

Andheri Kurla Road,

Andheri East, Mumbai - 400093.

Maharashtra, India.

Phone: 0091-22-28258136 / 0091-22-28258137

Fax: Fax: 91 22 28256147

E-mail: micromec63@gmail.com

info@micromechworks.com